Solid Works

Design is not just what it looks like and feels like. Design is how it works…

Design is not just what it looks like and feels like. Design is how it works…

Course Has been created to provide the CAD knowledge in the Industrial Level, This course has been created exactly how the industry projects will be executed to produce Quality products to the Clients.

I am sure after taking this course with proper practice with the material provided in the course the students can execute the Operations as per the industry needs.

While Explaining the Part Modelling and Drafting Manufacturing methods has been explained clearly and how a designer should adopt his design methods according to the manufacturer needs.

Apart from the Design for manufacturing and design for assembly this method of Designing can be followed to produce even automation works also.

Engineers, Design enthusiasts, Mechanical Engineers, Automobile Engineers

-Introduction

-Mouse Controls

-Different Sketch Profiles

-Copy of the sketch

-Patterns of the Sketch

-Constrains

-Dimensions

-Trim Command

-Notes Creation

-Sketch Practice

-Method of Design for Manufacturing

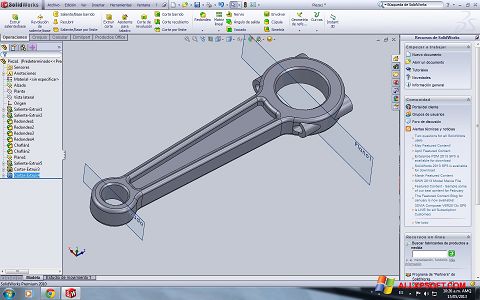

-Extruded Boss and Extruded Cut

-Revolved Boss

-Revolved Cut-Sweep Boss

-Sweep Cut

-Lofted Boss

-Lofted Cut

-Boundary Boss

-Boundary Cut

-General Hole creation Method

-Threaded Holes

-External Threads

-Fillet and Chamfers

-Types of Fillet and Chamfer

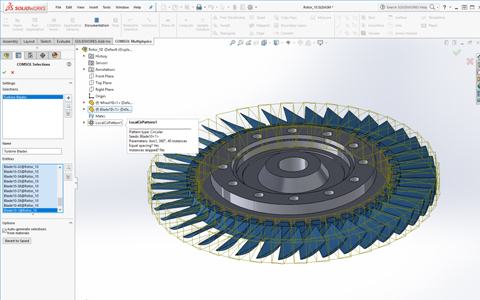

-Pattern and its Types

-Linear Pattern

-Circular Pattern

-Sketch Driven Pattern

-Rib Supports

-Draft Modelling

-Thin or Thick Shell

-Mirror of the Features

-Different type of Plane Creation Methods

-Helix and Spiral Curves

-Different Configurations

-Part Modelling Practice

-Design Table for Multiple Configurations

-Part model Comparison at Different Revisions

-Introduction to Assembly

-Base Component Import

-Fixing the Base Component

-Child component Assembly method

-Using Different constrains

-Different Patterns in Assembly

-Linear Pattern in Assembly

-Circular Pattern in Assembly

-Copy of Child Components

-Bill of Materials

-Hiding a component

-Making a Component Transparent

-Configurations in Assembly

-Exploded View in Assembly

-Exploded Line Sketch in Assembly

-Assembly Features

-Assembly Practice

-Introduction To Drafting

-Selecting Sheet Its Size and Sheet Standards

-Choosing the Model to Details

-Standard Views Creation Methods

-Model Views/ Custom Views

-Section Views

-Detail Views

-Broken View

-Broken Out View

-Crop View

-Auxiliary View

-Smart Dimensions

-Dimension Types

-Base Line Dimension

-Chain Dimension

-Ordinate Dimension

-Model Dimension

-Notes and Spell Check

-Surface Finish

-Hole Call Out

-GD&T and Datum Features

-Center Mark & Center Line

-Blocks and Hatching

-Revision Symbols and Tables

-Assembly Drafting

-Ballooning

-Weld Symbols

-Drafting Practice

-Quality Checking

-Drawings Comparison at Different Revisions

For any queries press the button.